Sustainability Highlights

2025 NEW

2025 Highlight Project 1

FITI Runs Together, Leading a Sustainable Wave

FITI Group — including FITI, FATI, Frontier, Kainova, and Fairtech — joined the 2025 Hsinchu City Marathon on November 16 (Sun). The group not only served as an event sponsor but also encouraged employees to take part, promoting health and demonstrating its commitment to corporate social responsibility.

The group has long supported employee wellness and fitness programs, fostering team spirit through various activities and helping employees build healthy habits. This reflects its ongoing dedication to sports development, employee well-being, and community engagement.

A total of 100 employees joined the race, including three executives who both ran and cheered for their teammates — showing strong leadership support for health and sustainability initiatives.

Embracing diversity, equity, and inclusion (DEI), 50% of participants were foreign employees. Their active participation highlighted Foxsemicon’s vibrant multicultural energy. Notably, several employees cycled 40 kilometers between Zhunan and Hsinchu to take part in a low-carbon way.

FITI Group will continue promoting health and sustainability events to create a resilient, diverse, and inclusive workplace — moving together toward a healthier and more sustainable future.

Total running 937KM

- about the distance around Taiwan

50%

of the sign-ups are foreign employees.

Colleagues from 3 countries

- joined the event.

SDG Links

SDG 3「Good Health and Well-being」:Encouraging employees to stay active through team participation to build healthy habits and a positive workplace.

SDG 10「Reduced Inequalities」:Nearly half of the 100 participants were foreign employees, showing diversity and equal opportunity.

SDG 11「Sustainable Cities and Communities」:The route highlighted Hsinchu’s culture and nature, promoting eco-friendly hydration and public transport.

SDG 17「Partnerships for the Goals」:The event strengthened teamwork and supported local community engagement.

2024 Highlight Project 1

Real-Time Carbon Emission Monitoring Technology

To support Net Zero, RE100, and green supply chain initiatives, FITI’s R&D developed a real-time carbon emissions monitoring system for wafer fab equipment. Sensors installed at electricity, compressed air, and vacuum inputs capture energy usage, enabling software to report hourly average emissions and cumulative emissions per equipment.

The system has been successfully applied to wafer sorters, showcased at SEMICON Taiwan, and featured in the 2024 ESG Friendship Challenge with a leading wafer foundry.

◎ Contributions and Expected Carbon Reduction Across the Semiconductor Value Chain

In response to the global Net Zero trend and sustainable supply chain management requirements, FITI has actively implemented real-time carbon emissions monitoring technology, with the following specific contributions and anticipated benefits:

1. Real-Time Carbon Emission Monitoring

New equipment integrates real-time carbon emission monitoring to provide transparent data for users and regulatory agencies, enhancing environmental information transparency.

2. Data-Driven Carbon Reduction

Accurate carbon emission data enable science-based analysis and strategy planning. Using predictive models and big data analytics, emission trends and key sources are quickly identified, supporting proactive energy-saving and decarbonization measures. The system also provides early warnings for anomalies, facilitating both preventive maintenance and improved energy efficiency.

3. Driving Value Chain Carbon Traceability

The widespread adoption of this technology enables traceability of carbon emissions across supply chains and streamlines verification under emerging international carbon standards (e.g., ISO 14064, SBTi). Enhanced data integration improves communication efficiency and promotes transparent information sharing across the industry value chain.

4. Continuous Innovation to Expand Industry Impact

FITI is committed to continuously integrating carbon emission monitoring functions into future equipment development. By collaborating with customers to validate application benefits, we seek to drive upstream and downstream partners toward low-carbon transformation, amplifying the multiplier effect of carbon reduction technologies.

SDG Links

Environmental (E): Enhance process transparency, optimize energy use, and mitigate climate change risks. (Supports SDGs 7, 12, 13)

Social (S): Support customers in responsible sourcing and sustainable supply chain requirements, strengthening collaboration with industry partners. (Supports SDG 17)

Governance (G): Promote more transparent environmental information disclosures and strengthen corporate governance and regulatory compliance. (Supports SDG 16)

2024 Highlight Project 2

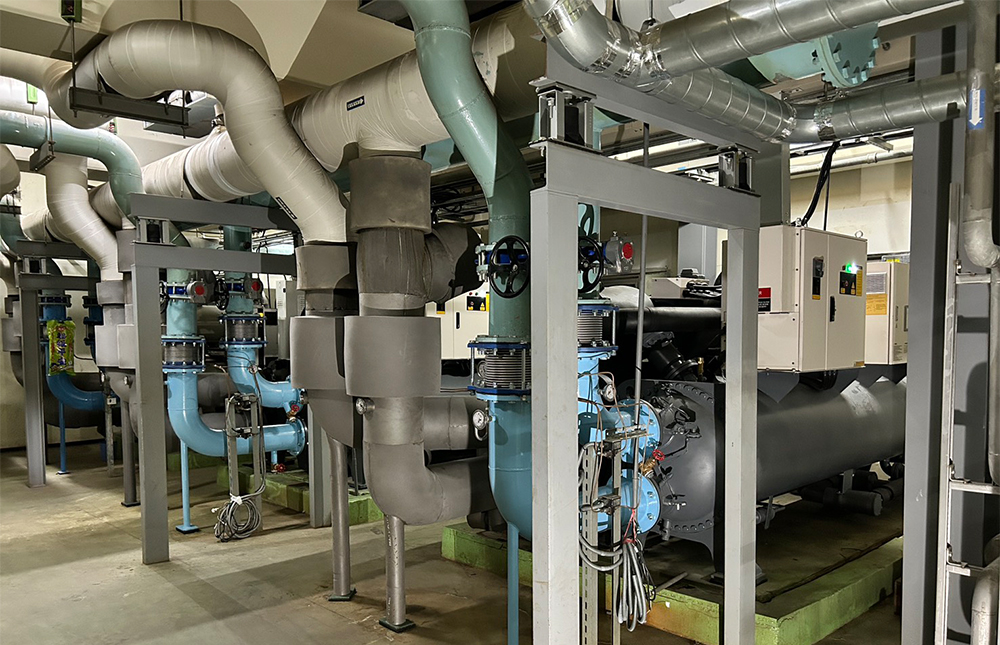

Smart, Energy-Efficient Chiller Replacement

Smart Chiller Upgrade for Low-Carbon Transition and Carbon Credit Earning

In collaboration with a domestic energy service company, FITI implemented a high-efficiency chiller replacement project at the Kezhong site in Taiwan by the end of 2024, adopting an innovative BOO investment model (Build, Operate, Own). The existing variable-frequency screw chillers were fully upgraded to the latest magnetic levitation (maglev) variable-frequency centrifugal chillers, which leverage maglev technology to achieve high efficiency and low energy consumption, significantly improving the site’s overall energy efficiency.

Preliminary estimates indicate that, following the upgrade, annual electricity consumption will decrease from approximately 2,057,525 kWh (baseline year: 2024) to 1,472,391 kWh, achieving a 28.44% energy savings. This corresponds to an annual reduction of approximately 291 tCO₂e, with a ten-year cumulative carbon reduction projected at 2,911 tCO₂e and total electricity savings of 5.85 million kWh.

This energy-saving project not only aligns with the Taiwan government’s energy policies and anticipated carbon fee regulations but also initiates the application for voluntary carbon credits approved by the Ministry of Environment. These carbon credits are expected to form a foundation for FITI’s future carbon neutrality strategy, enhancing market responsiveness within its carbon management system.

Additionally, the project reduces reliance on high-carbon facilities, lowering Scope 2 emissions, and marks a milestone in FITI’ s efforts toward low-carbon manufacturing and sustainable operations.

Looking ahead, FITI will continue to review low-carbon equipment upgrades, process optimization, and operational strategies in line with its medium- and long-term carbon reduction targets. Efforts will include expanding renewable energy use and incorporating carbon management performance indicators into departmental evaluations and decision-making processes, enhancing the measurability, traceability, and sustainability of our decarbonization actions.

This chiller replacement project also fostered the establishment of cross-departmental energy-saving collaboration, building experience that lays a solid foundation for future large-scale low-carbon equipment upgrades and improvements in energy efficiency.

Energy Saving Rate Achieved:

28.44%

Annual CO₂ Emissions Reduced:

291 tCO2e/year

SDGs Links

SDG 7: Affordable and Clean Energy

1.Upgrade to a high-efficiency water chiller system to improve energy efficiency ; 2.Reduce energy intensity and promote renewable energy adoption

SDG 9: Industry, Innovation, and Infrastructure

1.Adopt the new BOO model and promote energy-saving innovation ; 2.Strengthen digital and smart production capabilities

SDG 12: Responsible Consumption and Production

1.Achieve responsible production through equipment upgrades ; 2.Enhance energy efficiency and extend equipment lifecycle.

SDG 13: Climate Action

1.Annual carbon reduction of 291 metric tons; approx. 3,000 metric tons in 10 years ; 2.Align with the Taiwan government’s carbon pricing policies and apply for carbon credits, taking concrete actions to support climate adaptation and mitigation.

SDG 17: Partnerships for the Goals

1.Establish the innovative BOO investment model with energy service providers. ; 2.Promote collaborative carbon reduction through private and public partnerships.

2024 Highlight Project 3

Habitat and Biodiversity Protection

FITI’s Taiwan sites are located in the coastal area of Zhunan, Miaoli, which features diverse ecological zones, including mangrove forests, wetlands, and windbreak forests, providing critical spawning and nursery habitats for rare and endangered fish and shellfish. Since 2018, FITI has collaborated with local communities for six consecutive years to organize company-wide beach cleanups and ecological education, aiming for long-term conservation of local habitats—a contribution to the United Nations SDGs 14, 15, and 17.

In response to the UN Taskforce on Nature-related Financial Disclosures (TNFD) framework, FITI formally signed the “Biodiversity Protection Commitment” with the Wennei Community. We have jointly organized multiple employee training programs to raise environmental awareness and foster volunteer participation, laying the foundation for strengthened biodiversity management and advocacy.

Life Below Water

Protecting marine ecosystems

SDG 14

Life on Land

Conserving terrestrial biodiversity

SDG 15

Partnerships for the Goals

Promoting cross-sector partnerships to achieve sustainable goals

SDG 17

2024 Highlight Project 4

Inclusive Workplace- Employment Support for People with Disabilities

Sustainability also involves fostering an inclusive and diverse environment where everyone can realize their value and purpose.

1.Project Overview

We believe that true sustainability includes providing opportunities for every member of society to find their stage. Since 2010, FITI has implemented the Employee Cafeteria and Downpastry projects to promote inclusive employment for people with disabilities. By integrating social initiatives into daily operations, these have become a key component of our sustainable corporate culture.

2.FITI’s Commitment and Action

(1) Employee Cafeteria

‧ Workplace Inclusion: FITI provides full-time positions in the Employee Cafeteria for people with disabilities through internships and direct hiring. This approach offers stable income and career development opportunities while fostering a workplace atmosphere of respect and equality.

‧ Skills Development: Daily operational training helps employees with disabilities build service and food & beverage management skills, enhancing their self-worth and future employability.

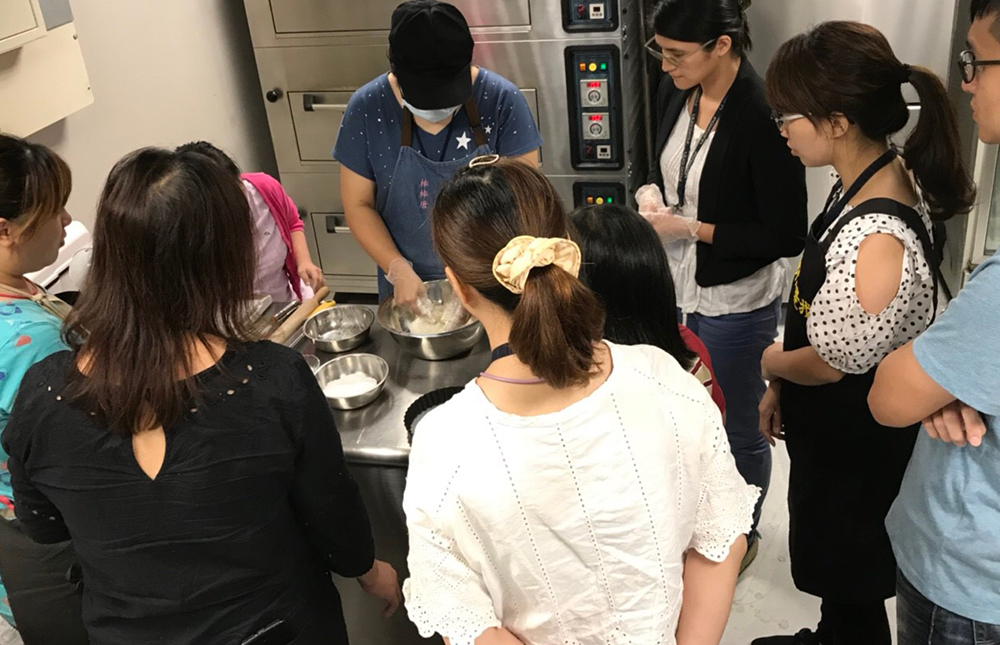

(2) Downpastry

Background: Established in 2018, Downpastry was initiated by parents of children with Down syndrome who pooled resources to purchase baking equipment. Using space on the second floor of FITI’s Zhunan Kezhong site, the Downpastry provides them with workplace adaptation and baking skills training.

‧ Space and Resource Support: FITI offers the free use of site space, creating a friendly and barrier-free work environment.

‧ Market Linkage: FITI supports the Downpastry through purchasing baked goods for shareholder meetings, client visits, and seasonal gift boxes. FITI also organizes quarterly employee baking workshops and provides fresh, below-market-priced bread daily, creating a sustainable internal consumption cycle that supports both the employees and the business.

3.ESG Impact

‧ Environmental (E): The Downpastry uses fresh milk from a local Farm and traceable eggs, supporting local agriculture and reducing the carbon footprint of ingredient transportation, promoting sustainable consumption.

‧ Social (S): The Downpastry collaborates with local special education schools in Miaoli, providing students with workplace internships. In a safe and supportive environment, they develop professional skills and improve employment competitiveness.

‧ Economic (G): Through external sales and internal consumption, the bakery gradually establishes a self-sustaining business model that aligns with FITI’ s corporate social responsibility, creating value that combines commercial and social impact.

4.Looking Ahead

FITI will continue to deepen collaborations, expand work and internship opportunities, and promote a replicable inclusive employment model for people with disabilities. Simultaneously, we will continuously enhance product quality and café service standards, ensuring that sustainability is not just a concept but a daily, tangible practice.

SDGs Links

SDG 8– Decent Work and Economic Growth: Promote inclusive and sustainable economic growth by creating employment opportunities for people with disabilities.

SDG 10– Reduced Inequalities: Reduce social inequalities faced by vulnerable groups through skills training and workplace support.

SDG 12– Responsible Consumption and Production: Establish a sustainable model based on local sourcing and internal consumption support.